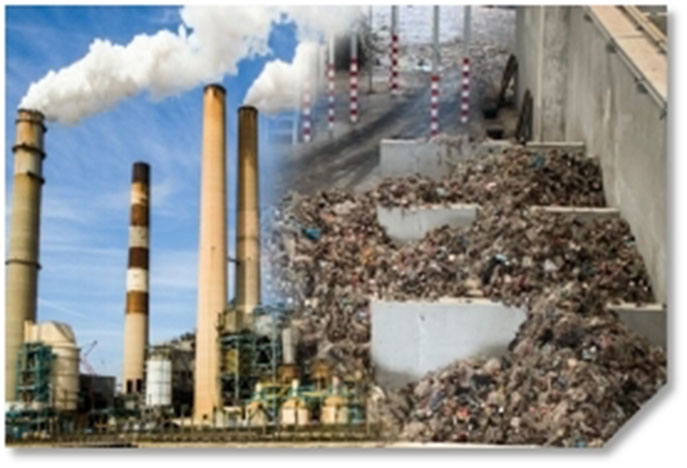

Waste Heat Recovery Boiler

The waste heat recovery boiler mainly utilizes the heat energy in the high-temperature flue gas generated during the incineration of garbage, which is converted to electrical energy or thermal energy by using specific technologies and equipment for energy reuse. This technology not only helps to reduce the pollution of garbage to the environment, but also effectively utilizes renewable energy and reduces dependence on traditional energy. The design and operation of the waste heat recovery boiler are aimed at maximizing the recovery of heat energy in the garbage incineration process, while ensuring that stack emissions meet environmental standards and reduce negative impacts on the environment.

Circulating Fluidized Bed Boiler

Circulating fluidized bed boiler is a highly efficient combustion technology., of which rapid fluidization is formed in the furnace to make small coal particles in full contact wtih the air for efficient combustion. This technology has characteristics such as high reliability, high stability, high availability, and optimal environmental protection. It is particularly suitable for processing low-quality fuels and various wastes, therefore, it has significant advantages in protecting the environment and saving energy.

In addition, the circulating fluidized bed boiler also shows its unique advantages in the handling biomass fuels, including forestry waste and agricultural waste, etc. The effective utilization of these wastes is of great significance in reducing environmental pollution and promoting resource recycling. Although circulating fluidized bed boilers face some challenges in terms of capacity and wearing, however, their advantages in environmental protection and energy efficiency make them one of the important directions for future development.

Biomass Boiler

Biomass boiler is a boiler that uses biomass energy as fuel. This kind of boiler can be divided into vertical and horizontal types in form, and it can be divided into power plant boiler, industrial boiler, domestic boiler, commercial boiler, etc. in terms of is application. Biomass fuel is a new type of renewable and sustainable green energy. As a boiler based on new energy, biomass boiler will gradually replace traditional boilers based on coal, oil, and gas, etc. Biomass fuel has basic characteristics of high volatility and low ignition temperature, therefore, theoretically any coal-fired boiler can burn biomass fuel. For biomass boiler, reasonable secondary air arrangement is considered in the design to ensure the huge amount of volatile matter that is instantly released during the combustion of biomass fuel can be fully burned, and at the same time ensure the residence time of flue gas in the furnace to avoid fine carbon particles being taken out of the furnace, so as to ensure that the fuel is fully burned in the furnace.

The characteristics of biomass boiler include automatic feeding and slag discharge, frequency variable adjustment of FD fan and ID fan, fully automatic operation of the boiler, automatic adjustment of fuel quantity according to load changes, and stable steam output. These boilers have multiple protection and alarm measures, such as pressure, water level, exhaust gas temperature, etc., to ensure the safe operation of the boiler. In terms of technical parameters, the rated steam output can reach 1-30t/h, and the rated steam pressure is 0.7-2.5MPa. Three national patent technologies are applied in the design of the biomas boiler, including the horizontal body three-pass design, the center symmetrical low-position arrangement of the furnace, and the full wet back structure, to ensure efficient and safe operation.

Biomass boilers are widely used in steel, metallurgy, petrochemical, textile, printing and dyeing, medicine, food, papermaking, rubber, plastics and other enterprises, as well as hotels, hospitals, schools, bathing centers and other places. These boilers not only provide stable heat and steam, but also are favored by more and more enterprises and institutions because of their advantages in environmental protection and energy-saving.

Hot Air Boiler

Hot air boiler is a thermal equipment that provides hot air flow for process needs. With integration of combustion and heat transfer processes, the boiler produces high-temperature flue gas by burning fuel, and heats up the air to provide the required hot air. Hot air boilers can be divided into two types according to their working principles and structure: heat storage type and heat exchange type. The heat storage hot air boiler can provide continuous high-temperature hot air with the heat storage device working in alternation (such as spherical hot air furnaces or hot air furnaces using checker bricks). . The heat exchange hot air boiler mainly relies on high-temperature resistant heat exchangers, such as ceramic heat exchangers, for heat transfer and air heating.

Heat storage hot air furnace

This type of hot air boiler stores and releases heat through checker bricks or other heat storage device to achieve air heating. Heat storage hot air boiler can be divided into top combustion type, internal combustion type, external combustion type, etc. according to the combustion method. Different combustion methods are used to increase the hot air temperature to meet the needs of processes such as blast furnace smelting. The advantages of the heat storage hot air boiler include high heat exchange temperature, high heat utilization rate, large working air volume, which is suitable for large-scale production needs. However, it also has some disadvantages, such as large size, large floor space, and unstable hot air temperature.

Heat exchange hot air furnace

This type of hot air furnace mainly relies on high-temperature resistant heat exchanger, such as ceramic heat exchanger, for air heating. The advantages of the heat exchange hot air furnace include high heat exchange temperature, small size, and stable hot air temperature, which are suitable for application scenarios with high requirements for space and energy efficiency. Nevertheless, its heat exchange temperature may not be as high as that of the heat storage type, and it is a relatively new product and has not yet been widely applied. In addition, coal-fired hot air boiler, as a new generation of heating products, adopts multi-head spiral groove heat exchange technology, with small footprint, easy installation and operation, stable performance and other characteristics, and is widely used in chemical, food, medicinal materials, tobacco, ceramics, building materials and other industries, such as material drying, spraying, dehydration and building heating. This information provides us with a comprehensive understanding of the different types of hot air boilers and their application areas.

Copyright ©2024-2025 GUANGXI JIUGUIJIEDA CONSTRUCTION ENGINEERING CO., LTD All rights reserved

联系电话:0771-3293872 桂ICP备2024036065号